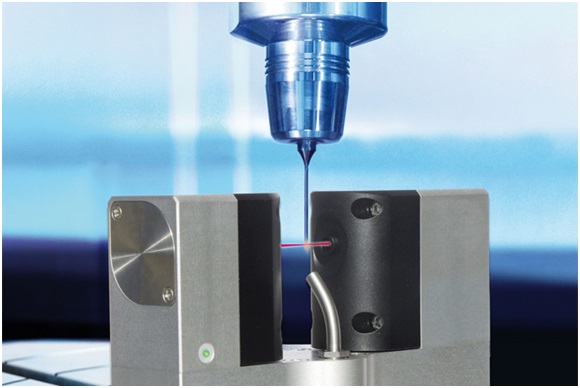

For manufacturers who want to improve efficiency, reduce bottlenecks, and maximize productivity, quality control is a major concern, and one of the best ways to guarantee quality control is through the adoption of coordinate measuring machines (CMMs). Assembly lines that use CMMs are often much more productive than those that rely on manual measurement for the simple reason that CMMs are much more likely to catch small errors before they become major problems.

A well-calibrated CMM running the most recent software is a powerful machine, and can save huge amounts of time and money in the long run, and hiring contract programmers is a great way to ensure your equipment is working at peak efficiency. While there are many reasons to contract out CMM programming services — and most production lines will need to hire contract programmers at one point or another — here are some of the most common CMM programming services that are contracted out:

Writing New Part Programs

Maximizing assembly line productivity means carefully mapping out each step in the process and finding the most efficient way to do it, which is why one of the most important services CMM contract programmers can provide is writing programs for new parts. If CMMs are not working from up-to-date electronic models, they cannot provide the best measurement solutions for your assembly line’s products.

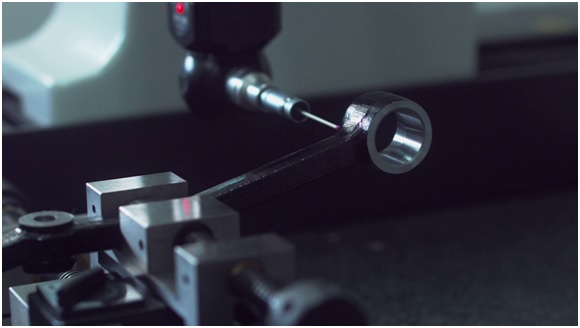

Contract programmers can be especially helpful if the part programs being written involve blades, gears, or complex geometry. They can also create guided routes for portable inspection processes involving ROMER Arms and other portable CMMs.

Modification Of Programs

Over time, most assembly lines will see changes and modifications to the parts they are producing, as the final product is adapted to better suit the needs of the market. In such cases, it is important to keep the CMM part programs up-to-date as well so that measuring errors are not introduced when old programs work off new blueprints. If you want to make changes to part programs as quickly and efficiently as possible, contract programmers are the best option.

Training And Support

Modern CMM equipment is extremely sophisticated, and every year brings new software developments and technological improvements that make CMMs even more useful for quality control and data gathering. If you are adopting new software, or updating existing software, contract programmers can be hired to train your in-house team on the latest CMM developments to help them stay on the cutting edge.

In addition to training staff on new features and software, contract programmers can also help explain how to get the most out of CMM equipment, how to integrate new programs and software into the assembly line, and how to use CMM programs as efficiently as possible.

It is often noted that manufacturing is an industry of margins: successful manufacturers are those who are best able to reduce overhead and ensure their assembly line is as efficient as possible, and making sure that CMMs are running the most recent software and the best part programs is a key part of this.

CMM contract programmers offer a wide variety of services that can help assembly lines stay as productive as possible by writing new programs, updating existing ones, and training in-house staff. If your assembly line needs technical help to guarantee its CMMs are as productive as possible, get in touch with a local metrology provider today.